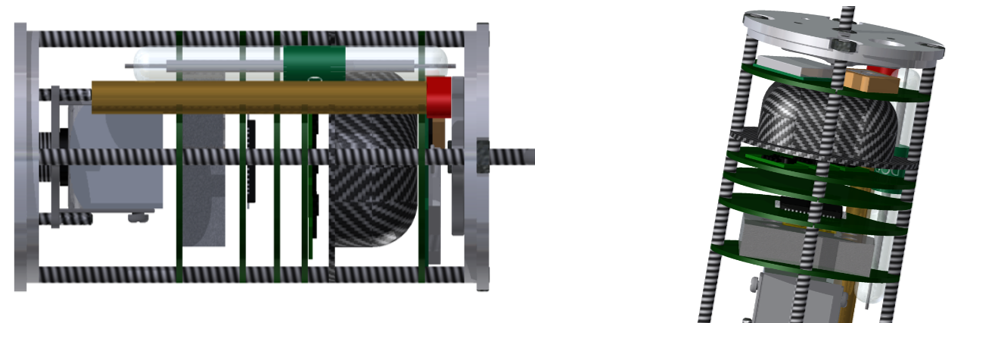

How our CanSat will look like? Well… quite like that:

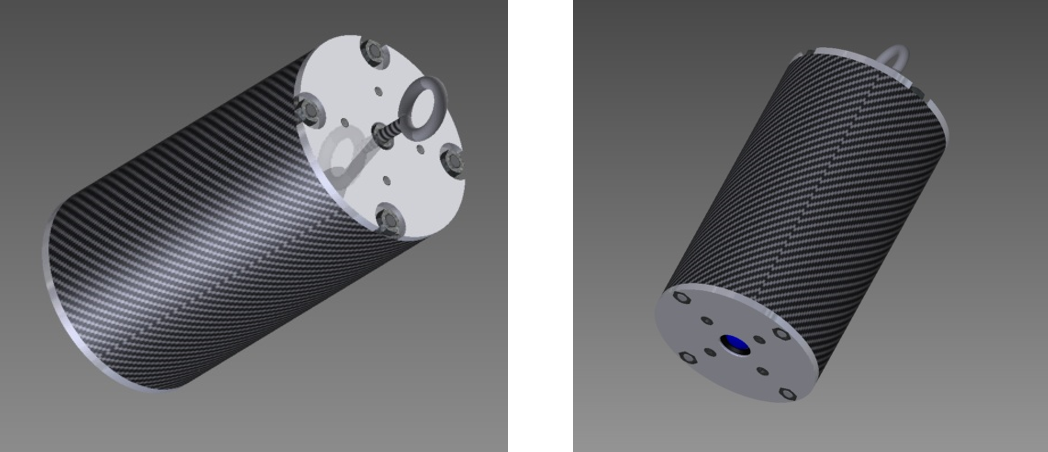

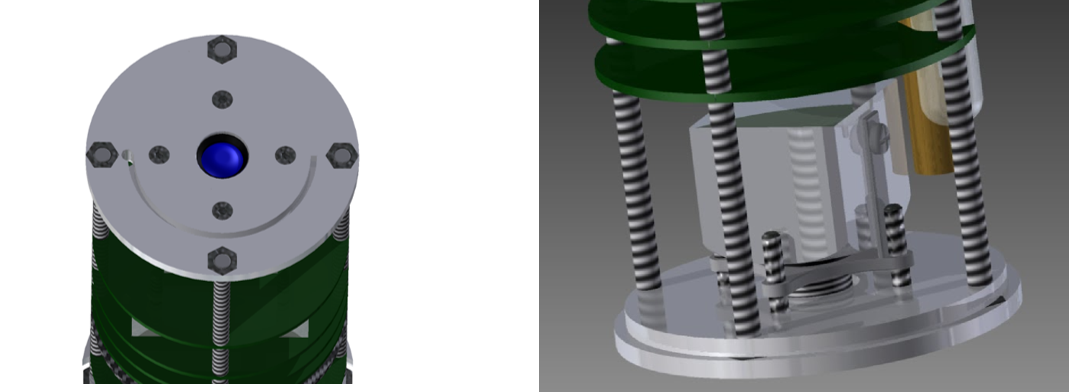

The top and bottom cover plates of the CanSat will be made of milled aluminum, the external casing of carbon-aramid fiber (Yup, we’ve got kevlar!) and the internal supporting elements will be 3D-printed. Four long screws going from the bottom to the top plate will bind and harden the structure. The case will slide along the whole satellite, allowing easy access to the internals before launch and after recovery. Gaps in top and bottom plates will give the camera view and allow air flow through the probe.

The camera will be integrated with the bottom plate with the fisheye lens looking through it.

The electronic components will be placed on five double-sided boards. The boards do not form full circles – this leaves room for the Geiger tube and <CLASSIFIED>, any required wiring (including the antenna, which will span most of the CanSat height) and air flow. Between boards a Li-Pol pack is located.